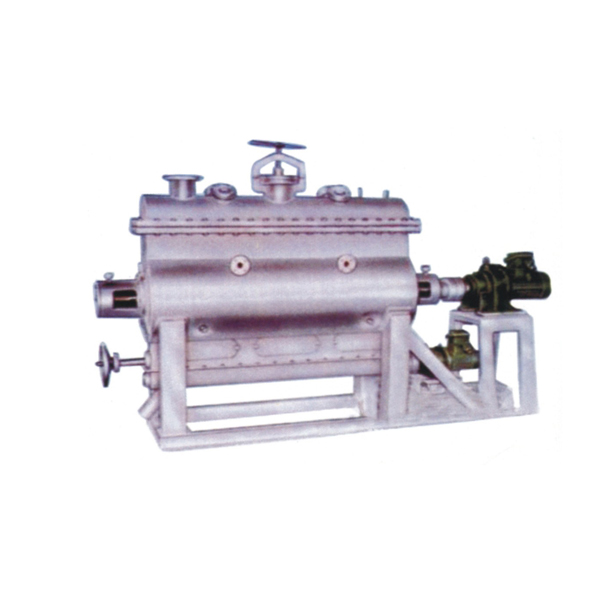

Renewable Design for Centrifugal Water Oil Separator - Seed tank – Nanquan Chemical

Renewable Design for Centrifugal Water Oil Separator - Seed tank – Nanquan Chemical Detail:

Fermentation equipment is a reaction device widely used for the growth of microorganisms. In the fermenter, various microorganisms are grown in a suitable environment, metabolism and fermentation products. Fermentation equipment has been widely used in the pharmaceutical, MSG, brewing, enzyme preparation, pigment, food and other industries.

The agitator is the main device in the fermentation equipment. By mixing the liquid, the fresh culture components, air and mycelium are thoroughly mixed to achieve mass transfer and heat transfer. At present, there are three basic forms of the agitator: flat leaf (straight leaf) , curved leaves, arrows. Curved leaves are used in the equipment provided by the company. The curved worm wheel agitator has a shearing effect on the fermentation broth, and the fermentation broth has radial and axial flow. Compared with the straight-blade worm gear agitator, the power consumption of the curved blade agitator is small under the same diameter, rotation speed, leaf width and the like, but the effect is very good, and has been generally adopted in China.

Parameter:

|

Nominal volume(m3) |

Cylinder diameter(DNmm) |

Barrel height(Hmm) |

Jacket diameter(DNmm) |

Mixing shaft speed(r.p.m) |

Mixing shaft power(KW) |

|

0.01 |

159 |

400 |

200 |

300-400 |

0.15 |

|

0.02 |

200 |

450 |

250 |

300-400 |

0.2 |

|

0.03 |

250 |

550 |

300 |

300-400 |

0.25 |

|

0.05 |

300 |

700 |

400 |

300-350 |

0.55 |

|

0.1 |

400 |

800 |

500 |

300-350 |

0.75-1.1 |

|

0.2 |

500 |

1000 |

600 |

280-340 |

0.75-1.5 |

|

0.3 |

550 |

1200 |

650 |

280-340 |

1.1-1.5 |

|

0.5 |

600 |

1650 |

700 |

280-320 |

1.5-2.2 |

|

0.7 |

700 |

1700 |

800 |

200-280 |

2.2-3 |

|

0.8 |

800 |

1600 |

900 |

200-280 |

2.2-5.5 |

|

1 |

800 |

1900 |

900 |

200-280 |

2.2-5.5 |

|

1.2 |

900 |

1800 |

1000 |

200-280 |

3-7.5 |

|

1.5 |

900 |

2200 |

1000 |

200-280 |

3-7.5 |

|

2 |

1000 |

2500 |

1100 |

200-260 |

4-11 |

|

3 |

1200 |

2600 |

1300 |

200-260 |

5.5-11 |

|

4 |

1300 |

3000 |

1400 |

200-220 |

7.5-15 |

|

5 |

1400 |

3200 |

1500 |

180-220 |

7.5-18.5 |

Product detail pictures:

Related Product Guide:

SWEP Inc.: Heat Pump Heat Exchanger | 2012-06-04 | Cone Coffee Filter

Wood smoke isn’t good smoke | Bar And Plate Heat Exchanger

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for Renewable Design for Centrifugal Water Oil Separator - Seed tank – Nanquan Chemical , The product will supply to all over the world, such as: Orlando , Barcelona , Porto , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!